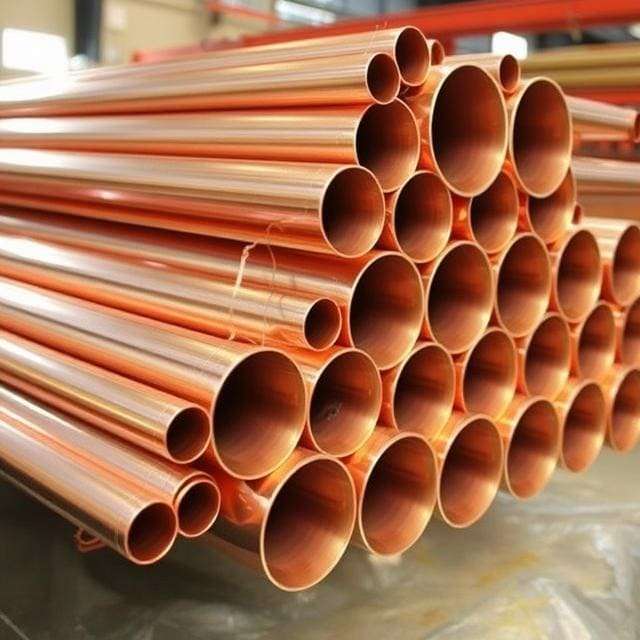

Grafton Pipe Fittings is a leading manufacturer and exporter of premium-grade Copper Nickel Pipes & Tubes, engineered to meet diverse industrial needs across global markets. Manufactured with precision and tested for durability, our Cu-Ni pipes are widely used in marine, offshore, shipbuilding, heat exchangers, condensers, and power generation systems. These pipes are available in various compositions, with UNS C70600 (90/10 Cu-Ni) and UNS C71500 (70/30 Cu-Ni) being the most commonly utilized grades, conforming to ASTM B466 and other international standards.

Copper Nickel alloys offer excellent resistance to seawater corrosion, stress corrosion cracking, and biofouling, making them ideal for saltwater piping and heat exchanger applications. At Grafton Pipe Fittings, we provide both seamless Copper Nickel pipes and welded Cu-Ni tubes with superior mechanical properties and consistent wall thickness. These pipes are manufactured in accordance with international standards such as ASTM, ASME, DIN, EN, ISO, and JIS, ensuring the highest quality for demanding applications.

Our Copper Nickel Tubes are supplied in annealed, pickled, or polished finish depending on the customer requirement. These tubes offer high thermal conductivity, excellent fabricability, and remarkable tensile strength, making them suitable for both low-pressure and high-pressure systems. The UNS C70600 (90/10) alloy contains 10% nickel, which enhances its resistance to erosion and impingement in turbulent sea environments. Meanwhile, UNS C71500 (70/30) offers higher strength and corrosion resistance, suited for more aggressive conditions such as high-velocity seawater.

Grafton Pipe Fittings provides Copper Nickel Pipe Fittings, flanges, elbows, tees, and reducers alongside the pipes and tubes to deliver complete piping solutions. Our tubes come in outer diameters ranging from 6mm to 219mm and wall thicknesses up to 20mm with lengths up to 6 meters or custom cut sizes. Whether for naval shipbuilding, desalination plants, or chemical industries, our Cu-Ni products guarantee exceptional performance and long service life.

Specification Of Copper Nickel Pipes & Tubes

| Grades | ASTM / ASME SA 312 GR. TP 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316L, 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . ASTM / ASME SA 358 CL 1 & CL 3 GR . 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316H , 321 , 321H , 347. |

|---|---|

| Seamless Size | 1 / 8" NB - 24" NB |

| ERW Size | 1 / 8" NB - 36" NB |

| EFW Size | 6" NB - 100" NB |

| Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB |

| Length | Single Random, Double Random & Required Length |

| Schedule | SCH20, SCH30, SCH20, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Types | Seamless / ERW / EFW / Welded / Fabricated / LSAW Pipes |

| Form | Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

World Wide Delivery

India India |

Mexico Mexico |

United States United States |

UAE UAE |

France France |

Saudi Arabia Saudi Arabia |

UK UK |

Taiwan Taiwan |

Singapore Singapore |

Iran Iran |

Nigeria Nigeria |

Malaysia Malaysia |

Italy Italy |

Canada Canada |

Germany Germany |

China China |

Belgium Belgium |

Thailand Thailand |

Iraq Iraq |

Ukraine Ukraine |

South Korea South Korea |

Qatar Qatar |

Poland Poland |

Costa Rica Costa Rica |

Oman Oman |

Romania Romania |

Kazakhstan Kazakhstan |

Jordan Jordan |

Angola Angola |

Philippines Philippines |

Egypt Egypt |

Colombia Colombia |

Australia Australia |

Chile Chile |

Norway Norway |

South Africa South Africa |

Japan Japan |

Morocco Morocco |

Portugal Portugal |

Russia Russia |

Czechia Czechia |

Hong Kong Hong Kong |

Spain Spain |

Tobago Tobago |

Netherlands Netherlands |

Turkey Turkey |

Greece Greece |

Indonesia Indonesia |

Kuwait Kuwait |

Sri Lanka Sri Lanka |

Venezuela Venezuela |

Cyprus Cyprus |

Myanmar Myanmar |

Bangladesh Bangladesh |